ABS

페이지 정보

작성자 Prime Link 작성일15-05-22 13:05 조회2,185회 댓글0건본문

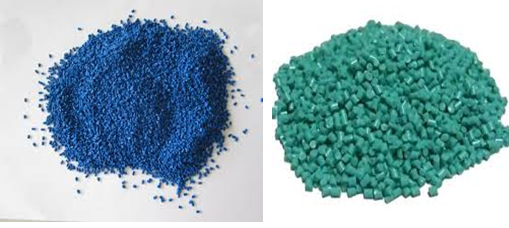

ABS (Acrylonitrile butadiene styrene)

1) ABS – General Purpose

Specific Gravity: 1.04

Molding Shrinkage, 3.2mm : 0.4~0.7%

Melt Flow Rate : 7 (g/10min)

Tensile Strength (3.2mm) @yield : 520

(kg/cm2)

Tensile Elongation (3.2mm) @Break : >

30%

Flexural Strength (6.4mm) :750 (kg/cm2)

Flexural Modulus (6.4mm) :26,000 (kg/cm2)

2) ABS – High Impact, High Toughness

Specific Gravity: 1.02

Molding Shrinkage, 3.2mm : 0.4~0.7%

Melt Flow Rate : 10 (g/10min)

Tensile Strength (3.2mm) @yield : 390

(kg/cm2)

Tensile Elongation (3.2mm) @Break : 30%

Flexural Strength (3.2mm) :630 (kg/cm2)

Flexural Modulus (3.2mm) :20,000 (kg/cm2)

3) ABS – Heat Resistance

Specific Gravity: 1.06

Molding Shrinkage, 3.2mm : 0.4~0.7%

Melt Flow Rate : 3 (g/10min)

Tensile Strength (3.2mm) @yield : 500

(kg/cm2)

Tensile Elongation (3.2mm) @Break : 20%

Flexural Strength (3.2mm) :800 (kg/cm2)

Flexural Modulus (3.2mm) :26,000 (kg/cm2)

Application: ABS's light weight and ability to be injection molded and extruded make it useful in manufacturing products such as drain-waste-vent (DWV) pipe systems, musical instruments (recorders, plastic clarinets, and piano movements), golf club heads (because of its good shock absorbance), automotive trim components, automotive bumper bars, medical devices for blood access, enclosures for electrical and electronic assemblies, protective headgear, whitewater canoes, buffer edging for furniture and joinery panels, luggage and protective carrying cases, small kitchen appliances, and toys, including lego and kreo bricks